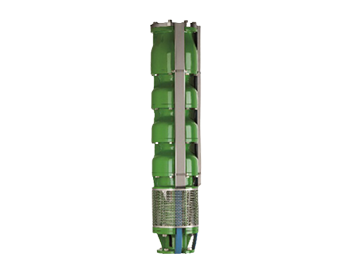

In general, borehole pumps are submersible centrifugal pumps of multistage design that can be submerged to great depths. Typically, they fit into narrow holes called boreholes, which are drilled to extract water from underground.

Motors used in boreholes are usually filled with water or oil for bearing lubrication and sealed with mechanical seals. The cable leaves the motor through a cable gland. The cable is manufactured according to the borehole depth.

How does the borehole pump work?

A motor drives a shaft, which in turn drives one or more impellers in a unit. The pump is positioned above the motor, with the motor at the bottom of the pump. In contrast to all other pump designs, the pump's intake is in the centre of the unit and its discharge is at the top.

As fluid travels through the first impeller, it passes through a suction strainer and is directed to the diffuser. If the pump has a single impeller, liquid passes around a non-return valve and exits the unit. If the pump design comprises multiple impellers, then the liquid passes across several impellers before passing around the non-return valve and leaving the pump.

Applications

Typical applications for borehole pumps include drainage, irrigation, drinking water supply

4″ Stainless Steel Submersible Pump

4″ Stainless Steel Submersible Pump

6″ Stainless Steel Submersible Pump

6″ Stainless Steel Submersible Pump

8″ Stainless Steel Submersible Pump

8″ Stainless Steel Submersible Pump