A multistage centrifugal pump has multiple liquid stages connected in series. Fluid enters the first chamber at suction line pressure and leaves at a higher pressure than when it entered. As soon as the fluid leaves the first stage, it enters the second stage where it is subjected to further pressure increases.The final discharge pressure depends on the number of stages the pump has however the flow range always remains constant for a given rpm

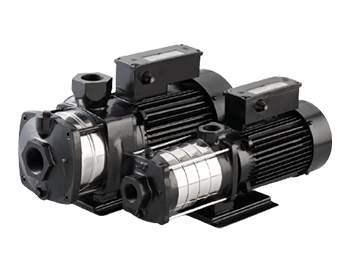

Multistage pumps are of two types-horizontal multistage pump and vertical multistage pump

Frequently Asked Questions

What are the benefits of multistage pumps?

Multistage pumps provide a better hydraulic lift. They are flexible and can be run at a lower speed if required. The hydraulic modules, the capability to supply additional impellers, and the ability to trim those impellers allow for meeting the duty point.

What are the differences between a single stage pump and a multistage pump?

A single stage pump uses one impeller whereas a multi stage pump uses 2 or more impellers. Diffusers are used in multistage pumps for channeling fluid. Multistage pumps have thrust balancing devices for shaft support.